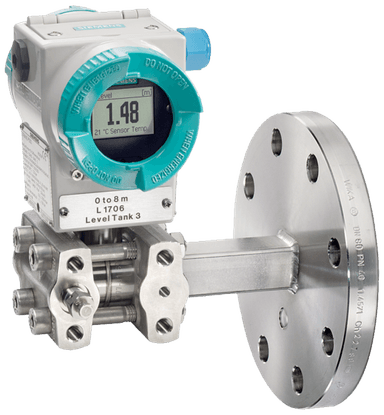

Siemens HART protocol

Benefits

- Service-proven analog measured value transmission

- Simultaneous digital communication with bidirectional data transmission

- Possibility of transmitting several measured variables from one field device (e.g. diagnosis, maintenance and process data)

- Connection to higher-level systems such as PROFIBUS DP

- Easy installation and startup

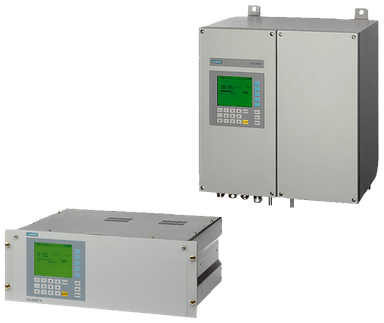

Use in conjunction with SIMATIC PDM

- Cross-vendor operation of all HART devices by means of standardized parameter records

- HART field devices that are described by HART DD are integrated in SIMATIC PDM through the HCF catalog. HART DD (Device Description) is standardized in SIMATIC PDM, multi-vendor and very widely used. Other HART field devices are integrated in SIMATIC PDM through EDD (Electronic Device Description)

- Easy operation and startup of field devices, also in hard-to-reach locations

- Expanded diagnosis, evaluation and logging functions

Application

These devices can be connected in different ways:

- Using the distributed I/O system

– SIMATIC ET 200M with the HART modules

– SIMATIC ET 200iSP with the HART modules

or with analog modules 4 to 20 mA and a HART handheld communicator - Using a HART modem, with which a point-to-point connection is established between the PC or engineering station and the HART device

- Using HART multiplexers, which are contained in the HART server of the HCF

similar products

Siemens Catalogue

View the Siemens Products for Process Instrumentation catalogue.