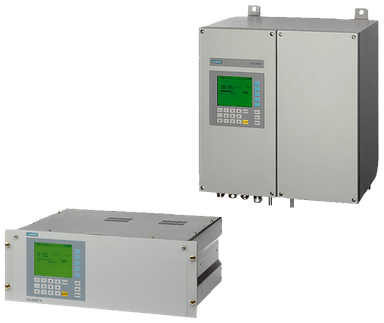

Siemens FIDAMAT 6 Extractive Gas Analyser

Siemens FIDAMAT 6 Extractive Gas Analyser

Benefits

The Siemens FIDAMAT 6 gas analyser is distinguished by its wide range of applications:

- In the presence of up to 100 % H2O vapor

- In ultra-pure gas applications

- With high-boiling components (up to 200 °C)

- In the presence of corrosive gases (with preliminary filter).

The FIDAMAT 6 exhibits:

- Extremely low cross-sensitivity to interfering gases

- Low consumption of combustion air

- Low influence of oxygen on measured value

The analyser is additionally equipped with warning and fault messages:

- For failure of combustion gas

- If the flame is extinguished

- To indicate pump and filter faults

Areas of application

- Environmental protection

- Wastewater (in conjunction with a stripping device, verification of the hydrocarbon content of liquids)

- TLV (Threshold Limit Value) monitoring at places of work

- Quality monitoring

- Process exhaust monitoring

- Ultra-pure gas measurements in media such as O2, CO2, inert gases and cold sample gases

- Measurement of corrosive and condensing gases

- Process optimisation

Further applications

- Chemical plants

- Gas manufacturers (ultra-pure gas monitoring)

- Research and development

- Cement industry (measurement of emissions)

- Paint shops and dry-cleaning systems

- Refineries (tank farms, wastewater)

- Drying systems

- Solvent recovery systems

- Pharmaceutical industry

- Automotive industry (engine development, engine and transmission development and certification)

Special applications

Special applications

Special applications are available on request in addition to the standard combinations, e.g. measuring range 0 to 100 %.

TÜV version

Measurement of flue gases according to 13th BlmSchV/17th BlmSchV and TA Luft for oil, coal, gas, and waste as fuels.

Furthermore, the TÜV-approved versions of the FIDAMAT 6 comply with the requirements of EN 14956 and QAL 1 according to EN 14181. Conformity of the analysers with both standards is TÜV-certified.

Determination of the analyser drift according to EN 14181 (QAL 3) can be carried out manually or also with a PC using the SIPROM GA maintenance and servicing software. In addition, selected manufacturers of emission evaluation computers offer the possibility for downloading the drift data via the analyser’s serial interface and to automatically record and process it in the evaluation computer.