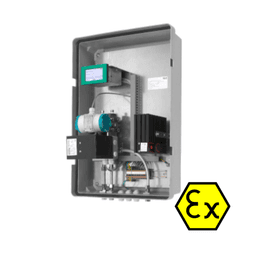

SKI LSE-HD Back Purging Unit

Even robust flow measurement systems such as averaging pitot tubes reach their limits in applications with high amounts of dust and particles. To ensure safe and stable flow measurement at high dust concentrations of up to 50 g/m³ we have developed the LSE-HD back purging unit. Taking into account the negative experience users have had with solenoid valve-based solutions we offer an improved solution for real long term stabilty.

The back purging unit is fully automated and enables maintenance-free operation even under challenging conditions. The LSE-HD is compatible and tested with all differential pressure based flow measurement methods and can be easily retrofitted in most cases. Due to the robust construction and the use of stainless steel for all wetted parts it is particularly suitable for rough industrial applications. It can be equipped for use in hazardous Ex zones or in difficult outdoor conditions. To protect the differential pressure transmitter it is usually integrated into the enclosure of the LSE-HD.

Its unique operating principle sets the LSE-HD apart from conventional purging units by cleaning positive and negative pressure side separately to avoid cross contamination and ensure proper removal of blockages. This becomes clear when you have a look at nature think about your last cold and blowing your nose. Only if the unblocked nostril is closed will it be possible to remove the blockage of the other nostril. This is no different with blockages of differential pressure sensors such as averaging pitot tubes.

- Differential pressure based flow measurements (with averaging pitot tube, venturi tubes, etc.) are used in applications for air, exhaust gas or other fluids with high dust or particle concentration of up to 50 g/m3

- The measurement system has to be robust and well proven,

- Highest possible availabilty of the measurement system is required,

- The purging parameters have to be adjusted to the specific application.